Area B, 8 floor, Building 1, No 615, Ningqiao Road, Pudong, Shangha

Copyright © 2019

Powered by Alsovalue

T/R module RF Automatic Test System

Name: T/R module RF Automatic Test SystemDescription: This product is an advanced solution designed for automated RF testing of T/R models. Traditional testing methods typically require gold wire bonding before conducting RF tests, a time-consuming and complex process. In contrast, this product innovatively utilizes RF probes to directly contact the TR components for testing, eliminating the need for gold wire bonding and significantly enhancing testing efficiency and accuracy.

With high-precision RF signal processing capabilities, the product enables stable signal output and precise data collection through direct contact between the RF probes and TR components. This ensures that each test meets industrial standards, reducing testing time and production costs while improving overall testing efficiency and reliability.

Furthermore, the product features an easy-to-use interface and seamlessly integrates with existing production lines and testing systems, greatly enhancing compatibility and applicability. It is an ideal c

Name: T/R module RF Automatic Test SystemDescription: This product is an advanced solution designed for automated RF testing of T/R models. Traditional testing methods typically require gold wire bonding before conducting RF tests, a time-consuming and complex process. In contrast, this product innovatively utilizes RF probes to directly contact the TR components for testing, eliminating the need for gold wire bonding and significantly enhancing testing efficiency and accuracy.

With high-precision RF signal processing capabilities, the product enables stable signal output and precise data collection through direct contact between the RF probes and TR components. This ensures that each test meets industrial standards, reducing testing time and production costs while improving overall testing efficiency and reliability.

Furthermore, the product features an easy-to-use interface and seamlessly integrates with existing production lines and testing systems, greatly enhancing compatibility and applicability. It is an ideal c

- Outline

- Application

- Documents

TR Module RF Automated Test Equipment

High-precision, high-efficiency test solution designed for Brick TR Modules

Get Product InformationProduct Overview

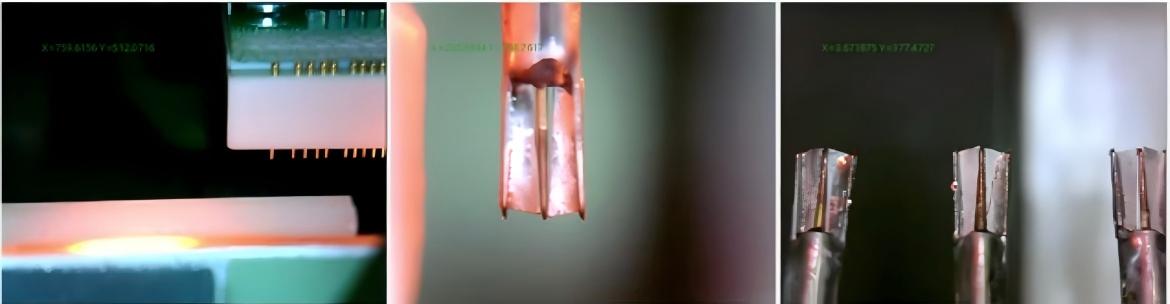

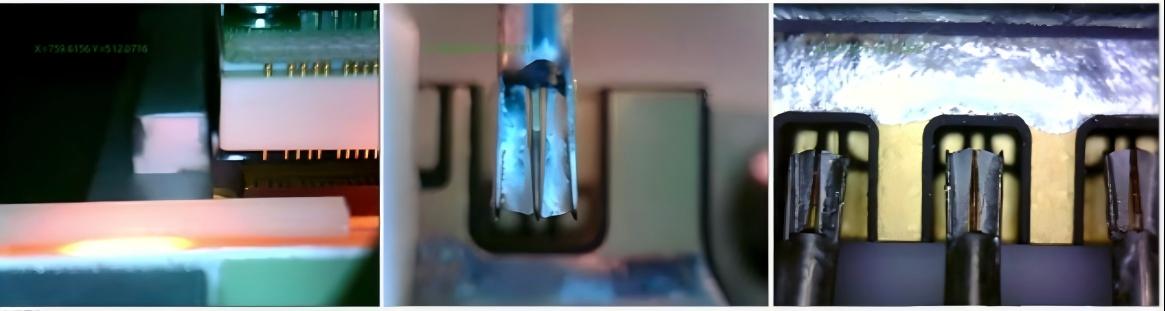

This equipment is custom-designed for RF and DC parameter testing of TR Modules. By integrating precision mechanical motion systems, multi-dimensional machine vision recognition, and intelligent algorithm control, it achieves full-process automation from loading to testing completion.

The equipment optimizes fixture design and probe layout for TR Module characteristics, significantly improving production testing efficiency and yield with 1μm-level control accuracy and excellent RF performance.

TR Module Compatibility

Compatible size: ≤55mm×55mm×5mm TR Modules. Supports quick switching between 4+ different module types.

Custom Fixture Design

Vacuum adsorption fixture designed for Brick TR Modules, tests 8 modules simultaneously with ±0.02mm tolerance

Multi-Probe Testing

Integrated RF and DC probes for simultaneous parameter testing

High-Precision Positioning

1μm control accuracy for precise positioning on small test points

Dual-Side Parallel Testing

Simultaneous dual-side probing for efficient batch testing

Intelligent Contact Detection

Machine vision algorithms accurately determine probe-to-pad contact

Complete Data Traceability

Automatic recording of all test data with export and analysis capabilities

Core Vision & Control Components

- Multi-camera layout: RF probe camera, DC probe camera, and module positioning camera

- Precision motor control: 5-axis motor modules with 1μm positioning accuracy

- TR Module Fixture: 8-station vacuum adsorption design, ±0.01mm flatness

- Specialized probe system: GSG structure for RF probes, POGO PIN for DC probes

Testing Process

Module Loading

Place TR Modules on custom vacuum fixture. After automatic fixation, transport to test position via feed motor modules.

Positioning Calibration

Positioning camera captures and recognizes module location for initial calibration.

Probe Positioning

Three-axis motor modules position probes near test area. Dedicated camera captures precise location data.

Precise Alignment

Motor modules position RF and DC probes precisely above corresponding pads.

Probe Descending

Probe descent module lowers probes incrementally while vision algorithms monitor contact status.

Parameter Testing

Automatic RF and DC parameter testing with synchronous data recording.

Reset & Transfer

Probes automatically reset. Tested modules are transferred to next station.

Performance Specifications

Testing Efficiency Metrics

Dual-side simultaneous probing for BTR Modules. Total time: 7s (base movement) + 15s/channel

| Brick TR Module Type | Test Channels | Per Group Test Time |

|---|---|---|

| 0408 Type TR Module | 2 Groups | 37s |

| 0612 Type TR Module | 1 Group | 52s |

| 0816 Type TR Module | 4 Groups | 67s |

Testing Accuracy Metrics

- Image recognition: 1μm/pixel, ≤1μm positioning accuracy

- Motor control accuracy: 1μm

- Return loss: ≤-25dB@DC~67GHz

- Insertion loss: ≤1dB@DC~67GHz

- Contact detection accuracy: ≥99.9%

- Prev: None

- Next: None